CMC-LX series motor soft starter

-

Category:Variable frequency energy-saving transmission

- Click count:

- Release date:2024/07/09

- Online inquiry

1、 Function:

CMC-LX motor soft starter is a new type of motor starting and protection device that combines power electronics technology, microprocessors, and automatic control. It can start/stop the motor smoothly without any step, avoiding mechanical and electrical impacts caused by traditional starting methods such as direct starting, star/delta starting, and self coupling voltage reduction starting. It can also effectively reduce the starting current and distribution capacity, avoiding investment in capacity expansion. At the same time, the CMC-LX soft starter integrates a current transformer inside, so users do not need to connect it externally.

2、 Features:

☆ Unique SCR triggered closed-loop control algorithm

Unique SCR closed-loop control function, specially designed for standard and heavy-duty loads. Users can choose between current limiting starting and voltage ramp starting based on load conditions, achieving an absolutely smooth torque free oscillation starting effect.

☆ High control accuracy, real-time efficiency

Adopting Cortex-M3 32-bit core CPU for central control, it has fast speed, high accuracy, and strong anti-interference ability.

☆ Beautiful appearance

The patent protected main circuit has a three in and six out structure, with a built-in current transformer scheme, making wiring convenient and high reliability.

☆ Standard MODBUS-RTU protocol that can be configured

Users can choose to order with or without the standard MODBUS-RTU communication protocol according to on-site needs.

☆ Integrate advanced protection functions

It has protection functions such as input and output phase loss, overload, overcurrent, phase current imbalance, thyristor overheating, etc., providing comprehensive protection for the motor and related equipment.

☆ All refractory materials

The structure below 90KW is a fully plastic shell, processed using flame-retardant ABS material. The upper cover of the power range above 90KW is a plastic shell structure, and the main frame is processed using aluminum zinc coated material, which has heat resistance and corrosion resistance characteristics.

☆ Externally accessible panels

The panel can be remotely connected to the device operating surface through the body interface for convenient on-site use.

☆ Easy maintenance

A monitoring signal coding system composed of 4-digit digital displays, which monitors the working status of system equipment 24 hours a day and provides fast fault diagnosis.

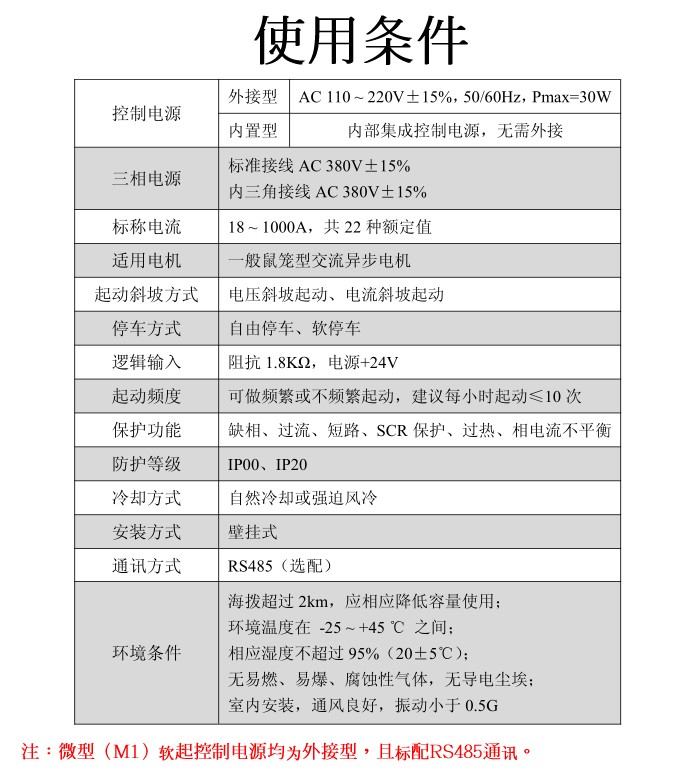

3、 Usage conditions:

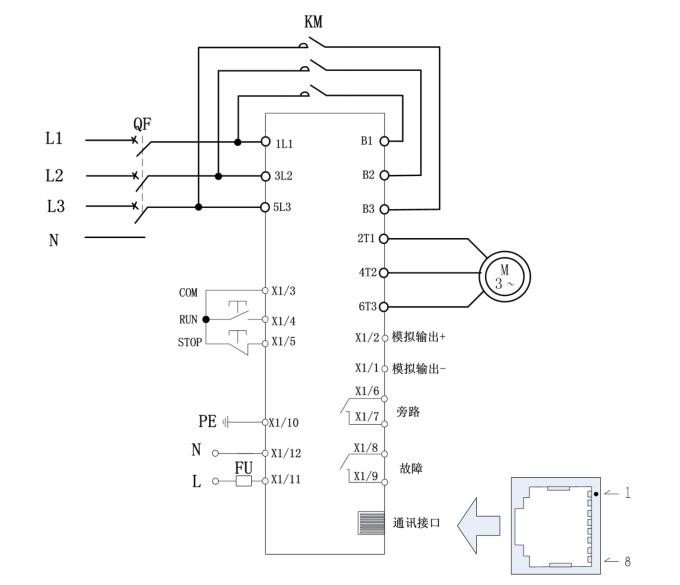

4、 Circuit connection

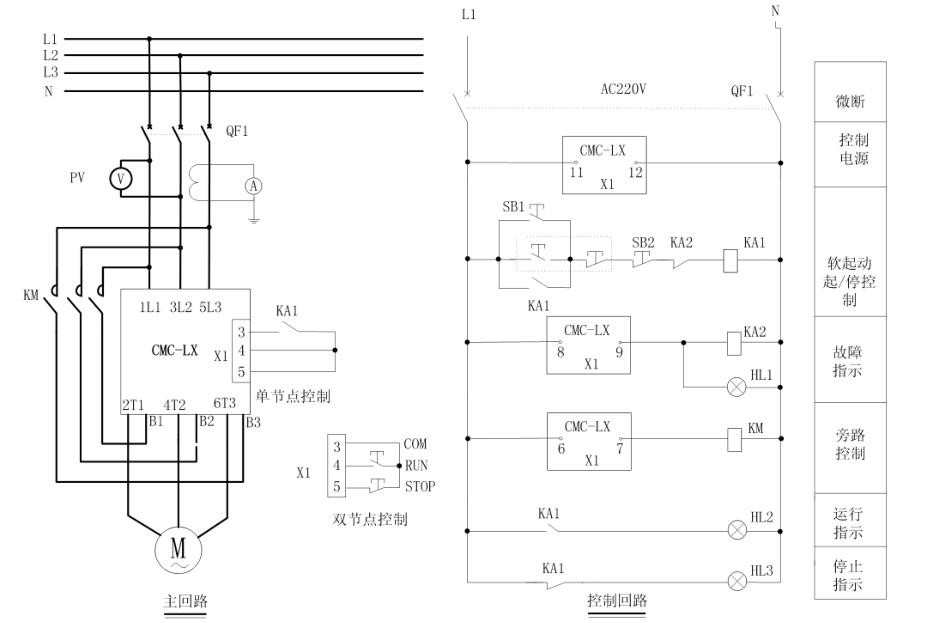

1. The terminals 1L1, 3L2, and 5L3 of the soft starter are connected to the three-phase power supply, and 2T1, 4T2, and 6T3 are connected to the motor. The soft starter can select whether to detect phase sequence through parameter settings. When using a bypass contactor, one side of the contactor is connected to soft starters 1L1, 3L2, 5L3, and the other side is connected to B1, B2, and B3.

Note: The communication interface is a functional optional port that uses fiber optic crystal head connection terminals, as shown in the figure, from pin 1 to pin 8 from top to bottom. Please refer to the terminal definition for specific terminal definitions.

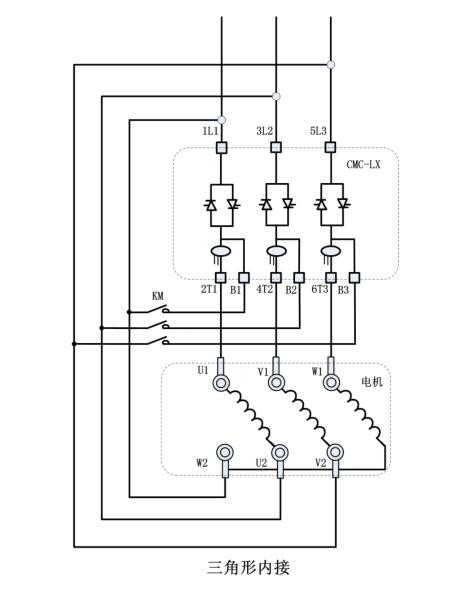

2. Triangle Inner Connection Diagram

If the user uses a triangular internal connection, they must strictly follow the following diagram for connection, otherwise it may cause damage to the motor or soft starter. Before starting the machine, the motor wiring will be checked. If there is a wiring error, the soft start will report a wiring error fault.

3. Typical application wiring diagram

be careful:

① The above figure shows a single node control method. Close the contact point for soft start, and open the contact point to stop the soft starter. However, it should be noted that this type of wiring LED panel startup operation is ineffective. The start stop signals of terminals 3, 4, and 5 are passive nodes.

② The PE grounding wire should be as short as possible, connected to the nearest grounding point to the soft starter. A suitable grounding point should be located on the installation board next to the soft starter, and the installation board should also be grounded. The grounding here is a functional grounding rather than a protective grounding.

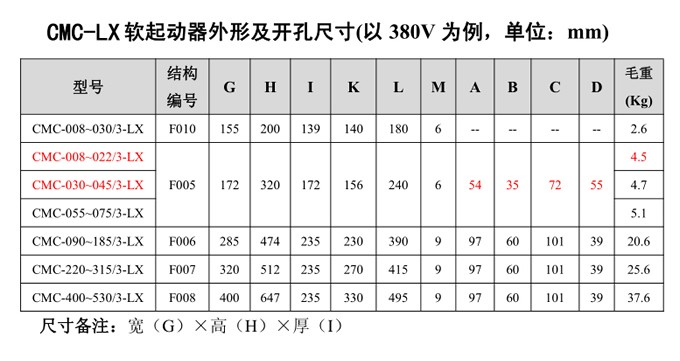

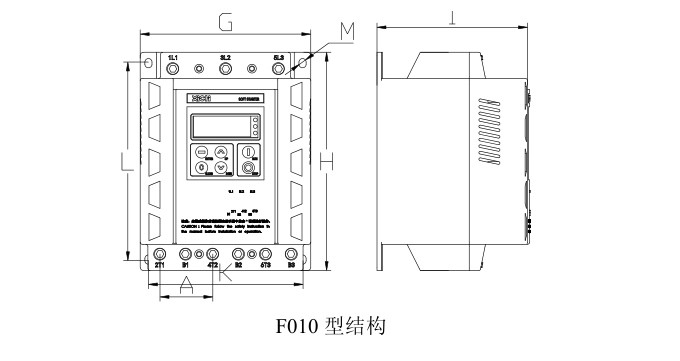

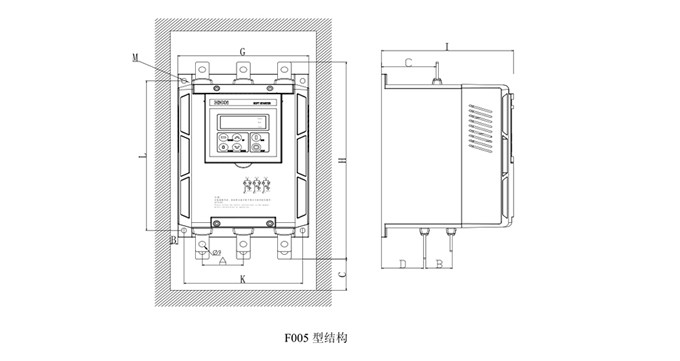

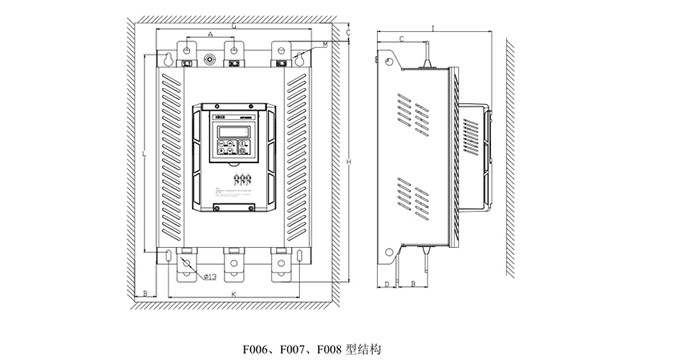

5、 Appearance and hole size (unit: mm, taking 380V as an example)

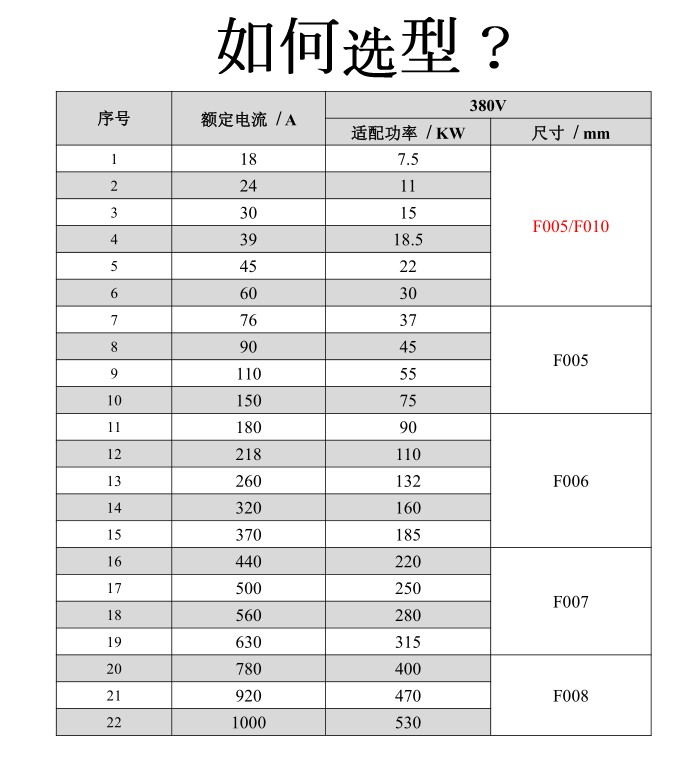

6、 Selection

Previous article:Goodrive800 series engineering drive frequency converter

Next article:CMC-MX series built-in bypass type motor soft starter