Remote monitoring system for pumping stations

-

Category:Industrial automation control

- Click count:

- Release date:2024/07/09

- Online inquiry

---Applicable scope---

The remote monitoring system for pumping stations is suitable for remote monitoring and management of urban drainage pumping stations. The pump station management personnel can remotely monitor the working status of the grid machine in the station, the water level of the sewage tank, the working status of the lifting pump group, the outgoing flow rate, and the concentration of harmful gases in the tank in the monitoring center of the pump station management office; Support manual control, automatic control, remote control of the start and stop of the grille fan, exhaust fan, and lifting pump; The panoramic view and important workstations within the image monitoring station.

---Applicable scope---

The remote monitoring system for drainage pump stations mainly consists of a monitoring center, communication platform, drainage pump station monitoring equipment, measurement and camera equipment.

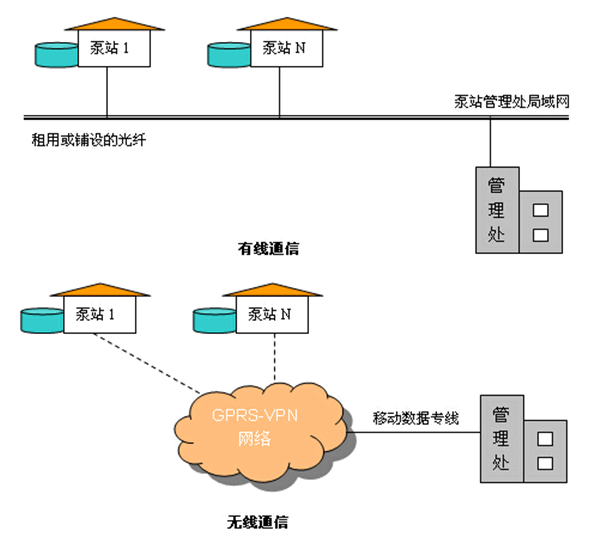

---Communication platform---

There are two commonly used communication platforms, one is wired communication: each booster pump station rents fiber optic communication with the management office, and the dispatch center, pump station monitoring center, and various functional departments communicate through local area networks. This communication platform can transmit continuous images. The second is wireless communication: each booster pump station communicates with the dispatch center through GPRS wireless network, while the dispatch center, pump station monitoring center, and various functional departments communicate through local area network. This communication platform cannot transmit continuous images.

---The functional characteristics of remote measurement and control terminals for pump stations---

◆ The measurement and control terminal is installed in the drainage pump station to monitor the liquid level of the sewage tank; Monitor the discharge flow rate; Monitor the start stop status, control mode, voltage, current, and protection status of the pump; Monitoring security alarms and inspections; Monitor the concentration of harmful gases.

◆ Support manual control, automatic control, remote control of drainage pump start and stop for water pump startup equipment, and support remote switching of control modes.

◆ Intelligent control of drainage pump rotation to achieve balanced wear and tear of all pumps.

◆ Adopting a distributed control mode, each pump station uses a main controller, and each drainage pump uses a sub controller. Whether the sub controller is put into use can be controlled.

◆ Automatically and remotely control the operation of the grating machine.

◆ Supports on-site industrial Ethernet communication, fiber optic communication, and GPRS wireless communication. Image monitoring is supported during fiber optic communication.

◆ Display the working status of the measurement and control equipment on site, display the working voltage and current of each water pump, and display the water level of the sewage tank.

◆ On site keyboard reading, modifying, and setting the working parameters of the measurement and control terminal.

◆ Regularly store on-site monitoring information for future reference.

◆ Proactively report alarms, such as liquid level exceeding limit alarm, water pump working state change, current and voltage exceeding limit alarm, etc.

◆ Support remote setting and modification of terminal operating parameters to achieve remote maintenance of terminal equipment.

---Main functions of pump station monitoring center---

◆ Data monitoring function:

--Monitor the start stop status, protection status, current, voltage, etc. of each drainage pump in each pumping station.

--Monitor the working status of the grid machines in each pump station.

--Monitor the liquid level, cumulative discharge, and concentration of harmful gases in the sewage tanks of each pumping station.

--Monitor the security alarm information of each pump station.

◆ Remote control function

--Remote control of the start and stop of each drainage pump and grille machine in each pumping station.

--Remote switching of control mode for each drainage pump in each pumping station.

◆ Alarm function

--Sewage tank liquid level exceeding warning water level alarm.

--When the device protection status occurs and the voltage and current exceed the limit, an alarm will be triggered.

--Illegal intrusion reporting and inadequate inspection reporting.

--Harmful gas exceeding limit alarm.

◆ Data storage

--Regularly store various monitoring data.

--Record event alarm information and monitoring data at that time.

--Record various operational information and monitoring data at that time.

◆ Information Service

--All monitoring information can be queried.

--All event alarm information can be queried.

--All operational information can be queried.

◆ Data report

Generate monitoring data and alarm data into reports, which can be exported and supported for printing and output.

◆ Video surveillance

Video is transmitted to the information center through on-site industrial Ethernet for real-time monitoring, video data storage, and playback. And it can remotely control the zoom and shooting direction of the camera.

◆ Interface

Real time monitoring data and video are displayed on the same interface, allowing for the monitoring of multiple pump station videos and data on the same screen, as well as switching to a single pump station for video and data display.

◆ Permission management

Grant different usage permissions to different users of operations.

◆ Extend

--You can freely increase or decrease the monitored pumping stations.

--It is possible to add, modify, and delete software functional modules.

--Reserve communication interfaces with other systems.

Previous article:Water source well monitoring system

Next article:Online monitoring system for sewage inlet and outlet water quality