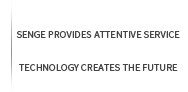

Air compressor solution

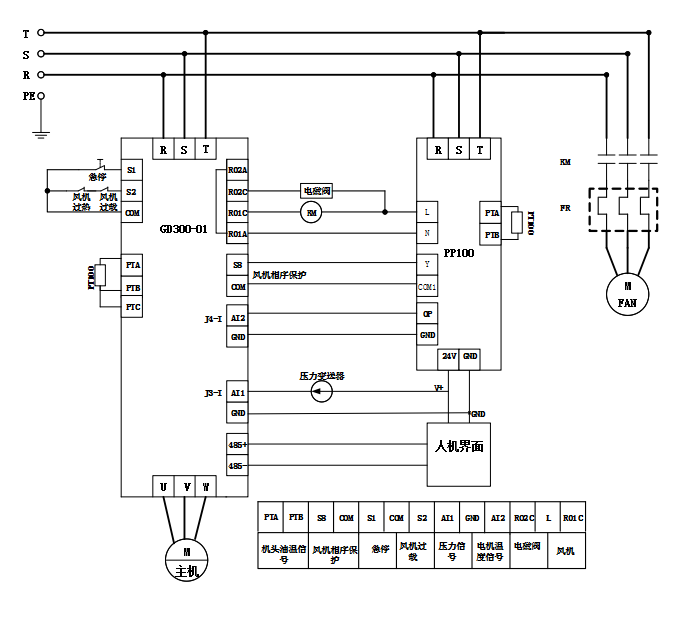

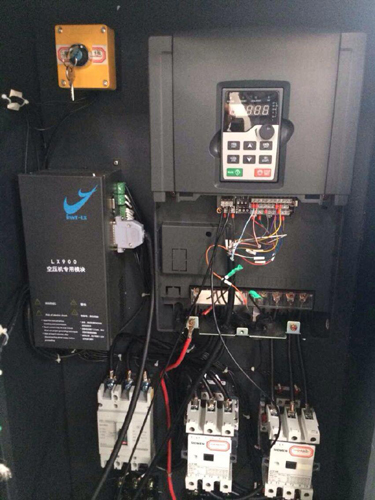

Communication address 2 of the main frequency converter

Communication format: Baud rate: 19200BPS, data format: Even parity (E, 8, 1) for RTU

Main frequency converter: GD300-01

explain:

1. The start and stop of the host are controlled by 485 communication, and the frequency is set to PID control to achieve pressure closed-loop control;

2. The control logic of the solenoid valve is implemented by the main frequency converter, used to control the intake valve, and is realized by the relay terminal. Special function: solenoid valve control output (28);

3. Connect the emergency stop signal to the switch input terminal and select the free parking function;

4. The temperature PID function is implemented by the main frequency converter;

5. The start and stop of the fan are controlled by terminals, and the control signal is given by the main frequency converter;

6. The fault signal of the fan is an external fault signal of the host;

7. Mechanical faults are identified by terminals, and the corresponding terminal functions refer to the main frequency conversion input and output terminal function planning. After mechanical faults are identified, the control screen performs alarm processing. (This function is reserved);

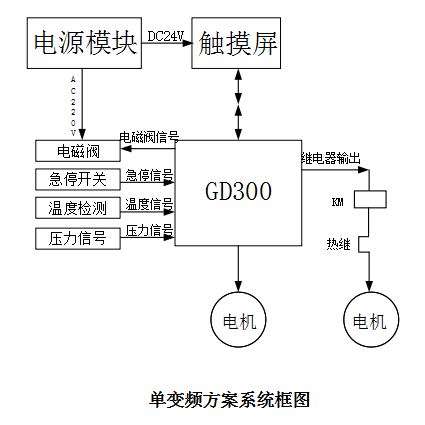

Introduction to background knowledge of screw air compressor system:

1. Basic structure of screw:

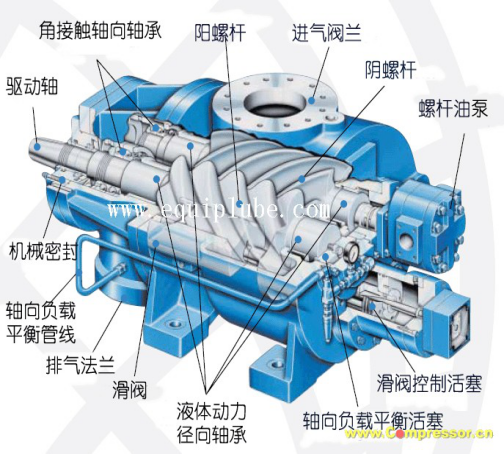

2. Screw air compressor system flowchart:

1- Air entry (air filter)

2- Compression rotor

3- After cooler

4- Air output

5- Oil and gas separator

6- Oil tank (oil gas separator)

7- Oil cooling

3. Working principle:

Air intake process: When the rotor rotates, the space between the teeth grooves of the male and female rotors is maximized when it turns to the opening of the air intake end wall. At this time, the space between the teeth grooves of the rotor is connected to the air intake. As the gas in the teeth grooves is completely discharged during exhaust, it is in a vacuum state when the exhaust is completed. When it turns to the air intake, the external gas is sucked in and enters the teeth grooves of the male and female rotors along the axial direction. When the gas fills the entire tooth groove, the end face of the rotor inlet side rotates away from the casing inlet, and the gas in the tooth groove is closed.

Compression process: At the end of inhalation, the teeth of the rotor will be closed to the casing, and gas will no longer flow out in the grooves. Its meshing surface gradually moves towards the exhaust end. The tooth groove space between the meshing surface and the exhaust port gradually becomes smaller, and the gas inside the tooth groove is compressed and the pressure is increased.

Exhaust process: When the meshing end face of the rotor is turned to connect with the exhaust port of the casing, the compressed gas begins to be discharged until the meshing surface between the tooth tip and the tooth groove moves to the exhaust end face. At this time, the space between the meshing surface of the male and female rotors and the tooth groove of the exhaust port of the casing is 0, which completes the exhaust process. At the same time, the length of the tooth groove between the meshing surface of the rotor and the intake port of the casing reaches the longest, and the intake process continues.

2、 Functional planning

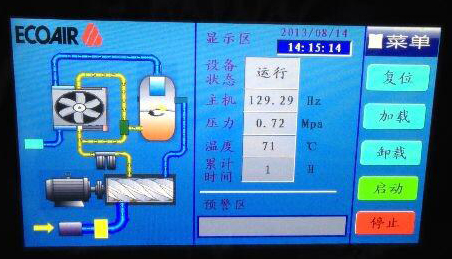

(1) Functional planning of user operation screen:

Touch screen model: VK070-N0CXR

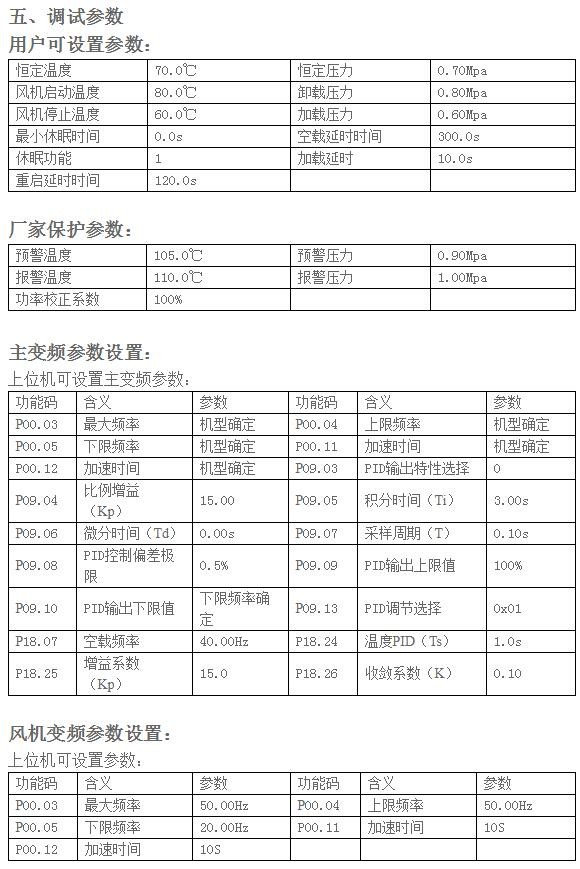

1. User set functional parameters

2. Display operating parameters

3. Control the start and stop of the main frequency converter

Note: Read the operating parameters of the frequency converter and send control start stop commands through 485 communication

(2) Main frequency conversion function

1. Main motor speed regulation

2. Electromagnetic valve control

3. Pressure signal sampling

4. Temperature signal sampling

5. Start stop control of fans

Main frequency conversion control logic:

function:

1. Electromagnetic valve control logic:

The frequency converter starts running and controls the loading of the solenoid valve based on the delayed loading time. During system operation, the loading and unloading of the solenoid valve are controlled based on the upper and lower limits of pressure. When the current pressure is greater than the upper limit pressure, unload; When the current pressure is less than the lower limit pressure, load.

2. During operation, PID operation is performed on the given frequency based on the pressure set value and pressure feedback value to control the speed of the main motor.

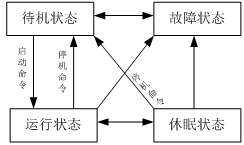

Sleep:

Empty state: The operating frequency is less than or equal to the empty frequency

No load delay time: duration of no load state

Idle sleep function:

When the no-load operation reaches the no-load delay time, the main frequency converter sleeps (closes the solenoid valve for unloading, and the main frequency converter stops). When the pressure is lower than the lower limit pressure (main frequency converter runs, opens the solenoid valve for loading)

Standby:

The system receives a shutdown command, the main motor slows down and stops, closes the solenoid valve for unloading, and enters standby mode;

Fan control:

1. Control the start and stop of the fan frequency converter through terminals based on the starting and stopping temperatures of the fan;

Input/output terminal function planning:

Switching input:

1. Emergency stop switch, input terminal function selection: free parking (6);

2. Fan frequency conversion fault input, input terminal function selection: external fault input (9);

3. Air filter blockage signal input, input terminal function selection: Air filter blockage signal (42);

4. Oil filter blockage signal input, input terminal function selection: Oil filter blockage signal (43);

5. Splitter blockage signal input, input terminal function selection: Splitter blockage signal (44);

6. Precision separator blockage signal input, input terminal function selection: Precision separator blockage signal (45);

Note: The polarity of the input terminal is determined by function code P05.10.

Switching output:

1. Electromagnetic valve control output, output terminal function selection: Electromagnetic valve control output (28);

2. Fan start stop control output, output terminal function selection: auxiliary motor start stop control (27);

Note: The polarity of the output terminal is determined by the function code P06 05 Decision.

Analog input:

1. AI1: Pressure signal input;

2. AI2: Temperature signal input;

(3) Fan frequency conversion function

The host sends a start stop control signal to the fan frequency converter through the switch output terminal based on temperature.

Input/output terminal function planning:

Switching input:

1. Fan start stop control input, input terminal function selection: forward running (1);

Switching output:

1. Fan variable frequency fault output, output terminal function selection: Variable frequency fault (5);

3、 Signal specifications

(1) Temperature sensor: PT100, using a temperature signal transmitter to convert the temperature signal into a current signal,

0~200℃——4~20mA;

(2) Pressure: 0-1.6MP-4-20mA, power supply voltage: 24V;

(3) Temperature transmitter specifications: input: pt100, temperature range: 0-200 ℃, power supply voltage: 24V, output: 4-20mA;

Product information: PT100 thermistor temperature signal transmitter

Main features:

>>Input: Pt100 (-200~+500 ℃) (range selectable)

>>Output signal: 4-20mA/0-5V

>>Auxiliary power supply: 5V, 12V, 15V or 24V DC single power supply

Or powered by 110V/220V AC power supply

>>Industrial grade temperature range: -45~+85 ℃

>>Accuracy level: 0.2 level (FSR%)

>>Contains linearization and long line compensation functions

>>Isolation and withstand voltage: 2500VDC (1mA, 60S)

>>Installation method: DIN35 rail installation

>>Size: 80x70x25mm

Input: Pt100 Temperature range: 0-200 ℃ Output: 4-20mA Power supply voltage: 24V

Part No.: WJ11-Z1-T4-P1-A4

Manufacturer: Shenzhen Weijunrui Technology Co., Ltd

(4) Fan speed regulation signal: 0-20mA

4、 System wiring diagram

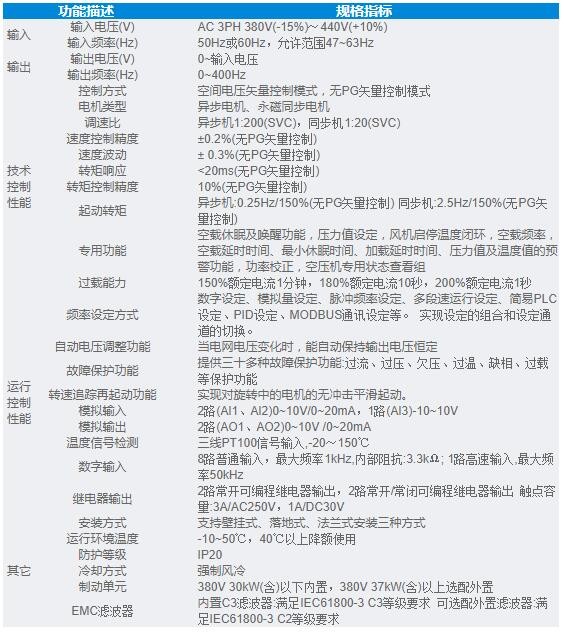

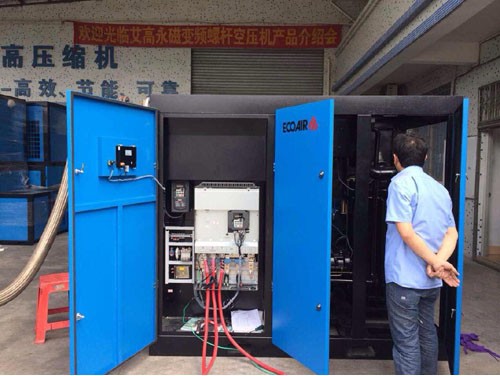

6、 Technical characteristics

Goodrive300-01 air compressor dedicated frequency converter is an air compressor industry specific frequency converter developed based on the Goodrive300 hardware platform, which can be widely used in air compressor applications. We provide a variety of external terminals to support multiple control methods, as well as PT100 temperature signal detection. The product's reliability and adaptability to the environment, as well as customized and industry-specific design, make its functions more optimized, applications more flexible, and performance more stable.

1. The integrated solution of touch screen and frequency converter saves the use of PLC, reduces wiring, facilitates operation, provides more complete protection, and reduces equipment failure points;

2.2. Visual control, through the touch screen, the frequency converter parameters and system control parameters can be set, and the equipment has regular maintenance functions;

3. Equipped with intelligent sleep and wake-up control technology, the system is safer, more energy-efficient, and more intelligent;

4. Excellent pressure PID control function ensures stable gas supply pressure of the air compressor equipment, and can monitor the pressure curve in real time on the touch screen;

5. Equipped with temperature warning and alarm functions, integrated with temperature control logic dedicated to air compressors;

6. The dual frequency conversion system has a constant temperature control function to ensure a constant exhaust temperature, and can monitor the temperature curve in real time on the touch screen;

7. Integrate PT100 interface and pressure signal interface, supporting 4 relay outputs;

8. The touch screen and frequency converter both have multi-level password permissions to avoid unauthorized operations.

7、 Parameter specifications

8、 Case and Attached Figures

Guangdong New Giant Wind, Guangzhou Aigao, Foshan Baode, Zhejiang Delayi, Ribao, and others account for 70% of the market.

Previous article:One to two water pump frequency conversion cabinet

Next article:Sugar mill sugarcane pile crane frequency conversion cabinet