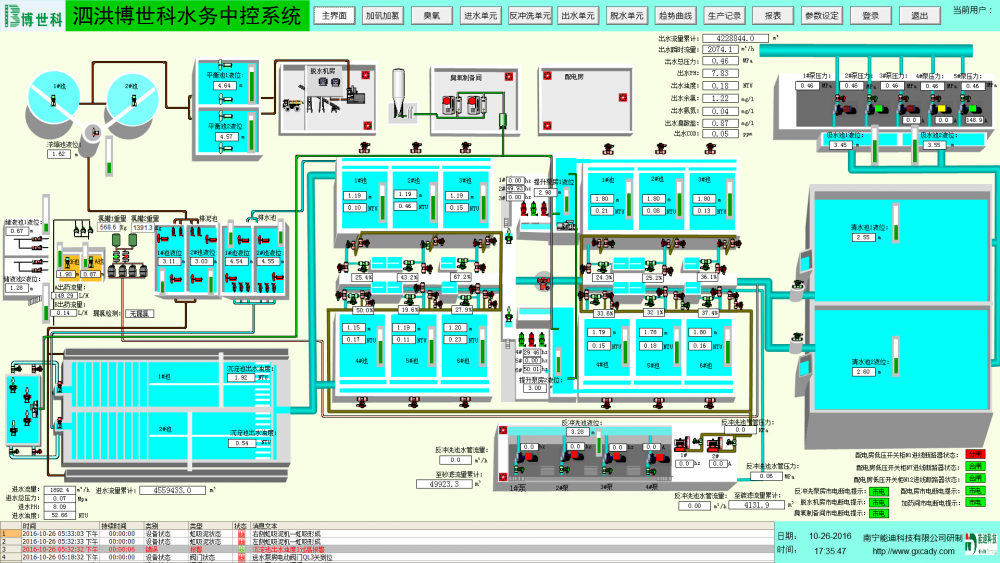

Sihong Southeast Area Water Supply Project

Introduction to the Automatic Control System Engineering of Jiangsu Sihong Boshike Water Purification Plant Project

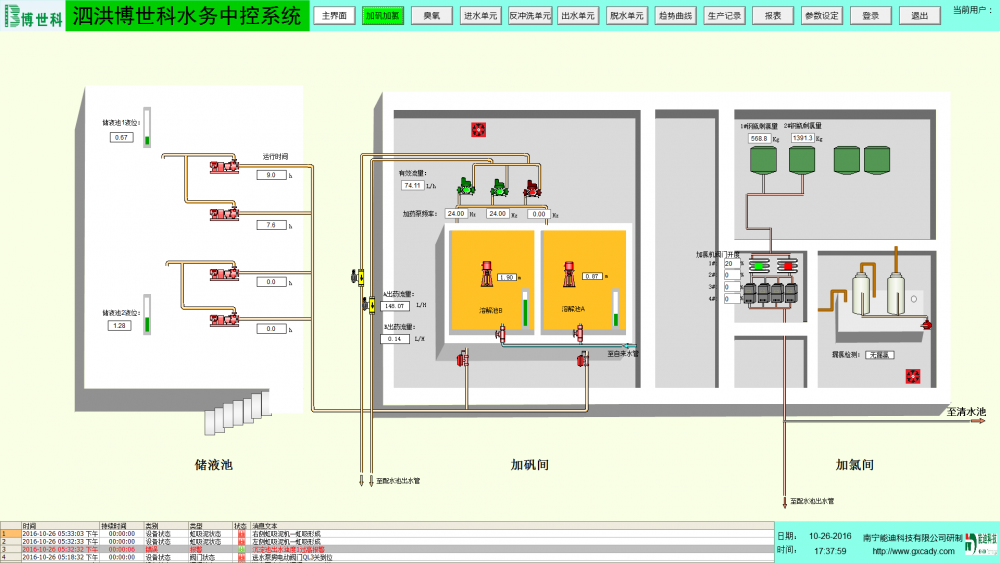

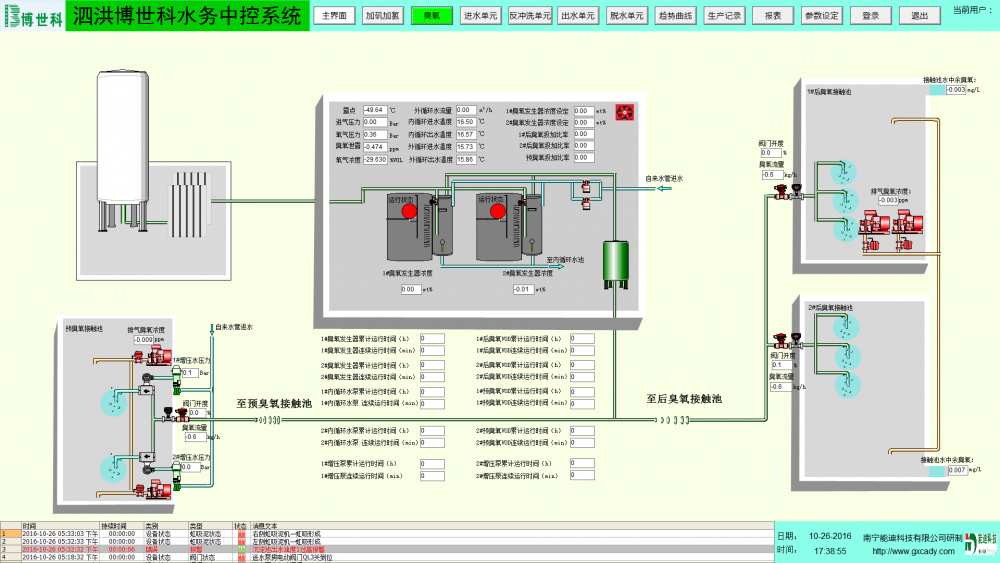

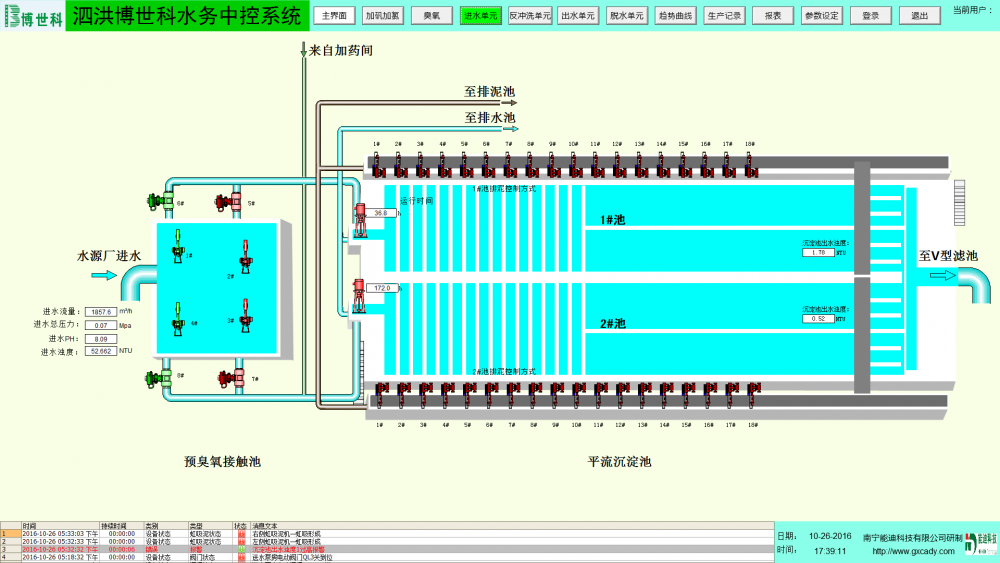

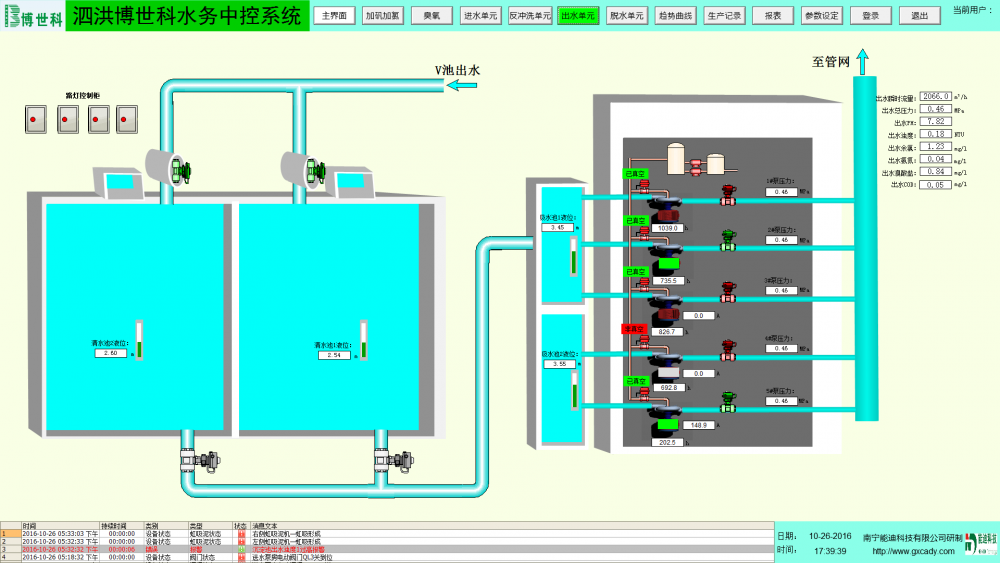

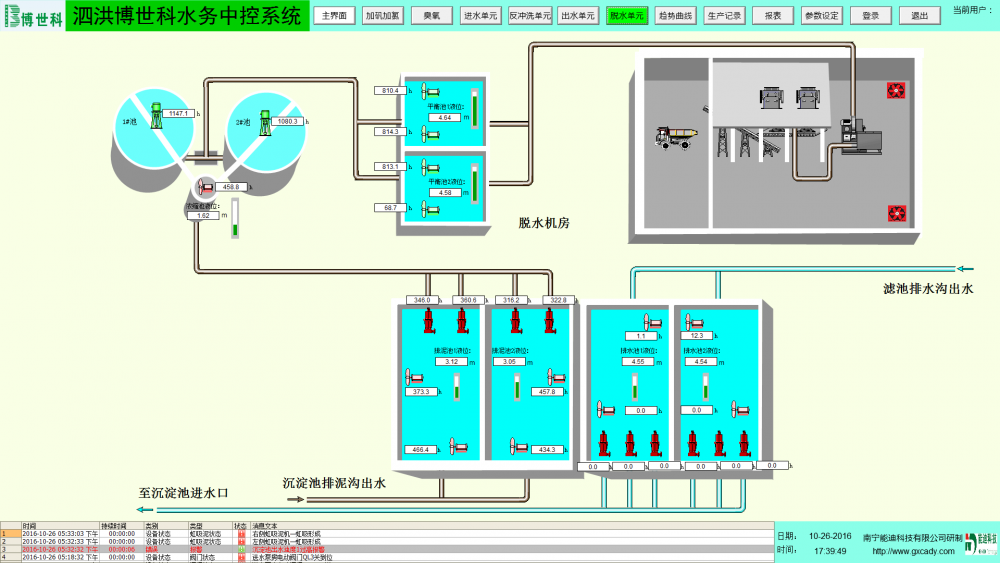

This project is located in Sihong County, Suqian City, Jiangsu Province. The self-control scope includes: PLC control cabinet (MA1) in the central control room of the comprehensive building, PLC control cabinet (MA2) in the transformer and distribution room, PLC control cabinet (MA3) in the backwash pump room, PLC control cabinet (MA4) in the dosing room, PLC control cabinet (MA5) in the ozone preparation room, PLC control cabinet (CD1-CD6) in the sand filter tank, PLC control cabinet (CD7-CD12) in the carbon filter tank, and PLC control cabinet (CD13-CD14) in the horizontal sedimentation tank. MA1, MA2, MA3, MA4, and MA5 are equipped with 10 inch touch screens using the S7-300 system; (MA6) CD1-CD6, (MA7) CD7-CD12, (MA8) CD13, and CD14 use the S7-200Smart system. Each console is equipped with a 7-inch touch screen, and data can be queried between each PLC system through the touch screens of each PLC control cabinet; The central control room of the comprehensive building is equipped with a 4-station control console and two upper computers with dual hot standby. Both the central control room and PLC cabinet of the comprehensive building are equipped with UPS

Among them, fiber optic switches are installed in the central control room of the comprehensive building, PLC cabinets in the transformer and distribution room, PLC control cabinets in the backwash pump room, PLC control cabinets in the dosing room, PLC control cabinets in the dehydration room, PLC control cabinets in the ozone preparation room, PLC control cabinet CD1 for the sand filter, and PLC control cabinet CD7 for the carbon filter, forming a fiber optic communication ring network.

The carbon filter and sand filter each have six control consoles, each using the S7-200Smart system. The filter console CD1 is equipped with an Ethernet switch, which is connected to CD2-CD6 through a Category 5 network cable. The Ethernet switch of the carbon filter console CD7 is connected to CD8-CD12 through a Category 5 network cable. The PLC control cabinets CD13 and CD14 of the horizontal sedimentation tank are connected to the fiber optic switch in the PL cabinet of the dosing room through a Category 5 network cable, and the data is uploaded to the upper computer in the central control room for display.

Previous article:Fengqing Yingpan Syrup Floatation Automatic Control System

Next article:Jiangcheng Town Sewage Treatment Plant (1)