Automatic Control System of Wuwei Town Sewage Treatment Plant

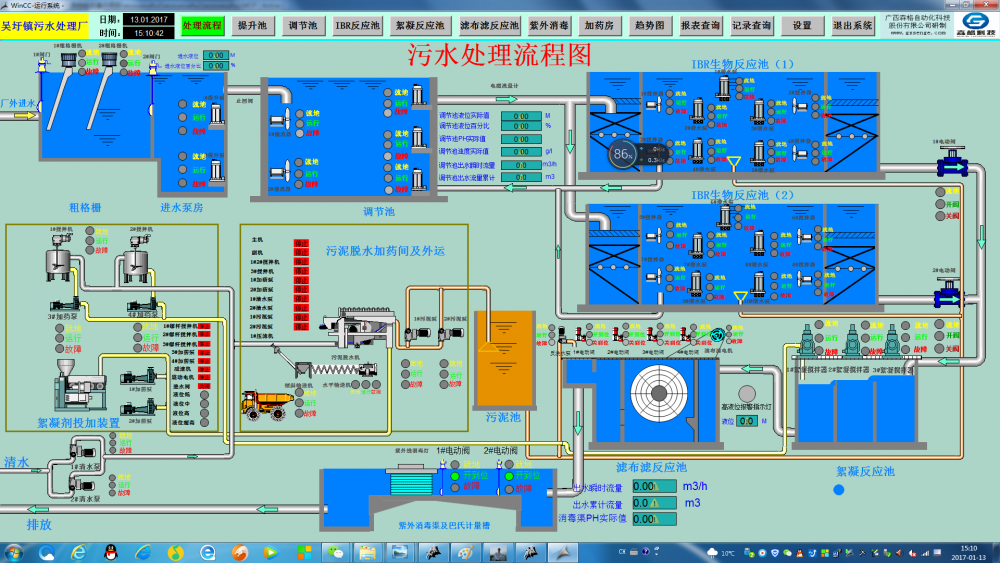

The main process of Wuwei Sewage Treatment Plant is IBR treatment, with an overall scale of 3000 tons per day.

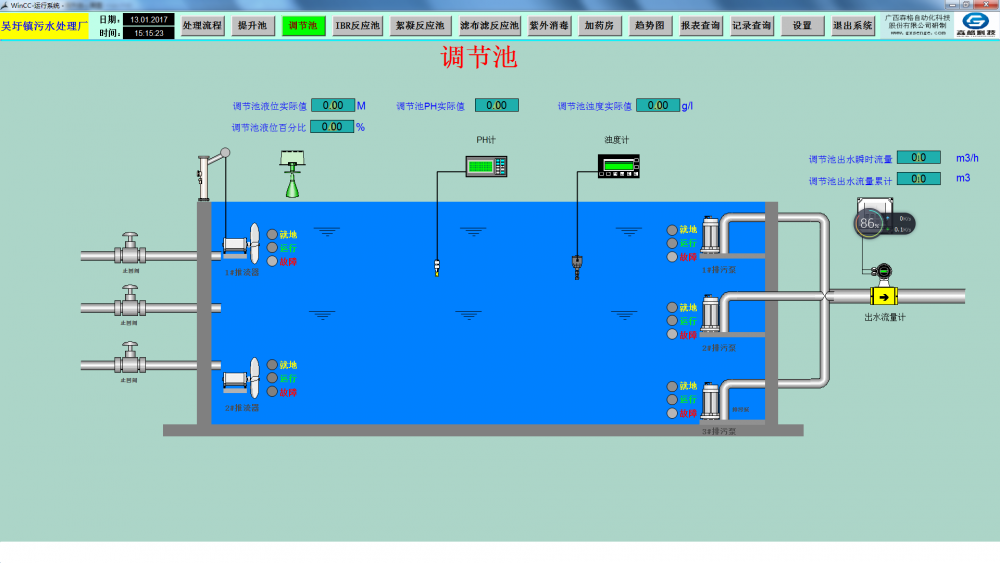

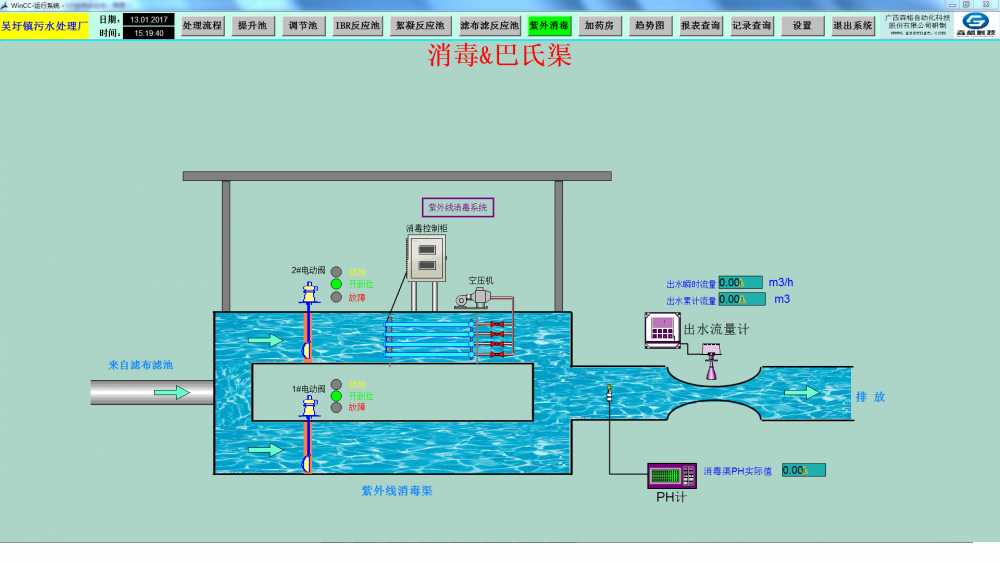

This project involves a Siemens S7300 PLC system in the main control room for centralized operation monitoring and decentralized process control of the sewage treatment plant. The system adopts PLC for real-time monitoring of the sewage treatment process, collects on-site data and equipment operation status, and controls the start and stop of each automatic on-site motor. The central control upper computer is equipped with UPS, which provides 30 minutes of operation time after a power outage.

The central control room is equipped with an industrial computer as the upper computer of the entire plant, which can centrally control and modify parameters of the entire system. It can also monitor changes in process parameters, equipment operation, and fault occurrence through various screens. The screens that can be displayed mainly include: process flow screens of various structures, process parameter screens, trend charts of process parameter changes, fault indication screens, equipment operation screens, etc. Staff can fully understand various parts of the processing process and timely grasp various situations that occur in each link.

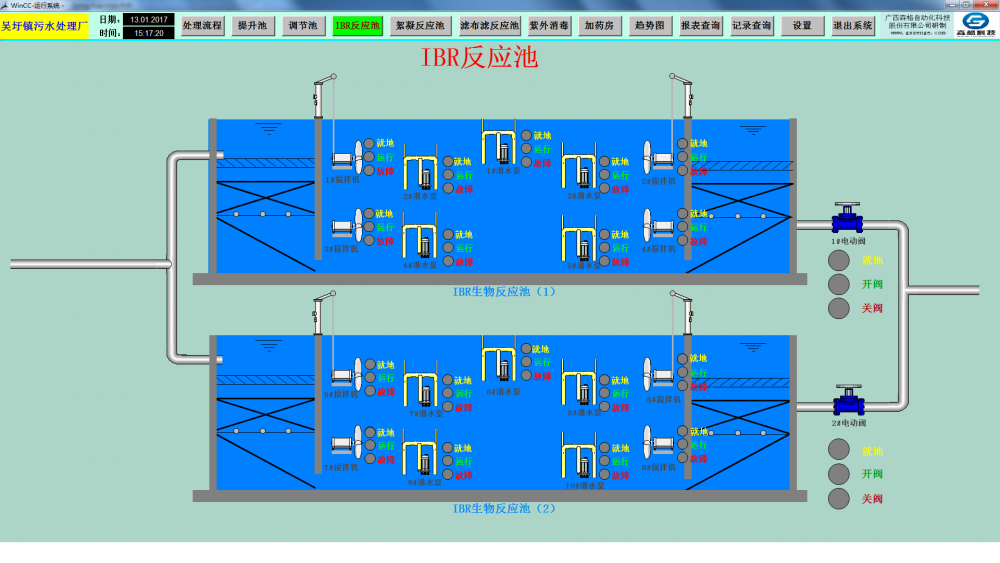

IBR生物反应池

IBR生物反应池

工艺流程图

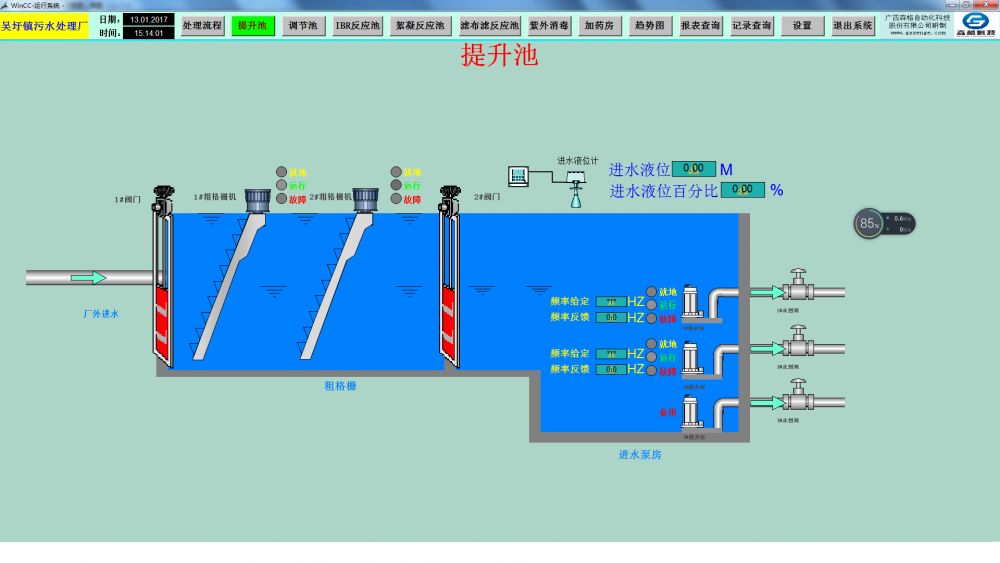

提升池

调节池

UV disinfection

Previous article:Integrated Control System for Central Air Conditioning in Guangxi Construction Building

Next article:Automatic Control System for Sewage Treatment Project of Daxinan Lingang Industrial Park in Fangchenggang City